Our Processing department processes various raw materials, including quartz sand, into individual semi-finished products in accordance with strict quality requirements and specific formulas. Once the materials are approved by the lab, the finished casting mass is mixed, before being poured into the casting moulds.

This is where the casting mass is moulded into shape. To achieve this, the foundry employees pour the mass into various moulds for the different sink models and initiate the hardening process. After a certain “baking time”, the SCHOCK sinks are ready, after which they are visually inspected and transferred to the Finishing department.

The Finishing department is where our sinks get their final look. First, the cast sinks are placed in our CNC machines. Next, the casting lip is removed by milling, and holes are drilled for the drain and fittings. After machining, employees measure the thickness of the material in different positions and make adjustments where needed.

The first step in the packaging process is the final quality control before our colourful sinks start their journey around the world. Then, the sinks are put though our packaging lines and are packed step by step by our employees. Drain fittings, maintenance instructions, tap fittings and other accessories, such as cutting boards and strainers, are also packaged in the corresponding boxes along with the sinks.

The top priority of employees in our Service & Maintenance department is to maintain the production processes with functional systems and operating equipment in all departments. With the right solution in their tool kit, they are close at hand to repair any faults and keep our production processes moving. The Service & Maintenance team also assists with the installation of new machines and systems.

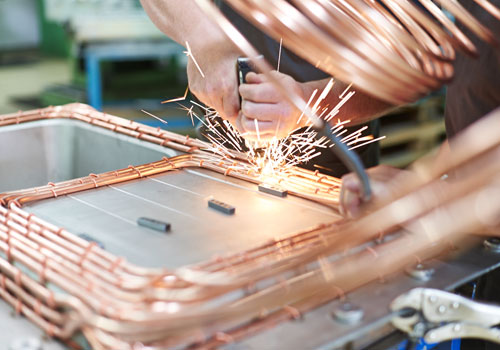

The perfect shape is what gives our sinks their unique design character. Our Mouldmaking department produces new moulds according to the specifications of the Design department. This includes welding and assembly work, as well as repair, maintenance, and refinishing of tool surfaces.

To ensure the high quality of our products, our Quality Assurance department conducts regular checks after every production step. If products do not meet the defined quality requirements and standards, corrective measures are taken. The team works closely with the different production departments. As well as checking outgoing goods, employees are also responsible for checking the quality of purchased parts on arrival.

After packaging, the sinks go directly to our Shipping department. There, our shipping staff load trucks and shipping containers according to a set list, and ensure that the load is secure before our sinks start their journey. At the same time, the team creates all the necessary shipping and customs documents, and issues export declarations for international deliveries.

Are you inspired by SHOCK and can’t decide?

Speculative applications are welcome any time.

Simply email us at:

BEWERBUNG@SCHOCK.DE

or take a look at our jobs portal in German at schock.de/jobfinder to see where we are currently in need of reinforcements: